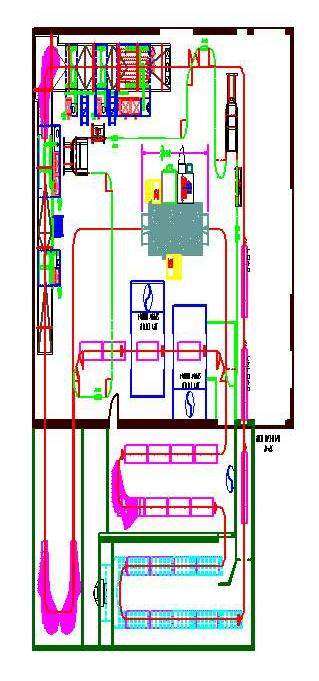

Paint-Line #3 Paint-Line #3

“Power and Free” Conveyor System to apply Surface Pretreatment, Shot Blasting,

Wet Paint or Powder Coatings.

The System consists of:

- One (1) “Power and Free”conveyor system, 600 ft of power chain, two (2) drives, 40 ft/min Transportation and 5 ft/min. processing speed.

2000 lbs/carrier load capacity.

- One (1) Five stage all stainless steel pretreatment washer

- One (1) Shot (steel grid) blasting room with blast application equipment.

- Two (2) In-line, back to back dry filter paint spray booth.

- One (1) Automatic-full recovery/recycle powder application booth.

- One (1) Dry off oven (direct gas fired)

- One (1) Wet paint /powder curing oven (direct gas fired)

- One (1) Forced air cooling tunnel

- Two (2) Load/unload stations

SYSTEM SPECIFICATIONS (Capacities) SYSTEM SPECIFICATIONS (Capacities)

|

Conveyor Speed

Max. Part Size

Max. Part Weight/Carrier

Max. Oven Curing Temperature |

40 ft/min. transportation/5 ft/min process

30” wide x 50” high x 96”long

2000 lbs

450 deg. F |

Note:

The phosphate free, five stage washer employs a new technology conversion coating formulated for use in the pretreatment of steel, zinc and aluminum surfaces to increase the adhesion and corrosion resistance of painted metal surfaces. This conversion coating process replaces traditional Iron and Zinc Phosphate products, while reducing the environmental impact.

|